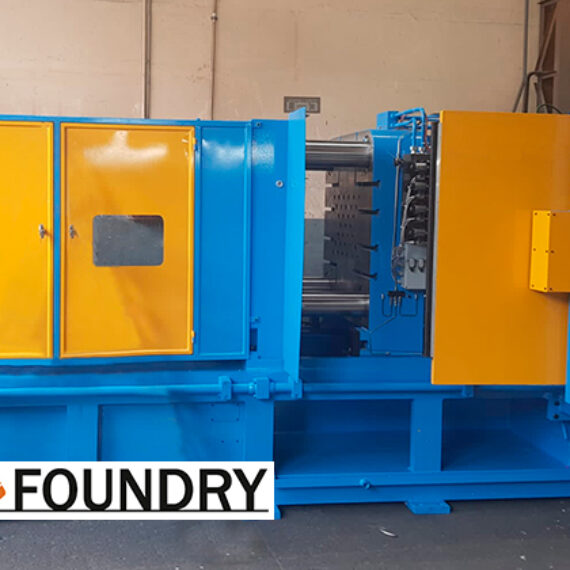

SA-Foundry sp. z o.o. (Poland) at the end of 2020 put into operation a foundry complex, based on the tilting gravity die casting machine ALG-1500*1300 (of its own design), at one of the factories in Ukraine. The complex is designed for the automatic production of pump casings from aluminum alloys weighing up to 50 kg.

This foundry complex includes: a melting / holding furnace, a pouring robot, a tilting gravity die casting machine and allows to obtain high-quality gas-tight castings from aluminum alloys. The maximum dimensions of the die are 1200*1000 mm. Controlled die filling with melt guarantees large and demanding castings of a wide range of applications.

Photo 1: Foundry complex based on the SA-Foundry ALG-1500*1300 tilting gravity die casting machine. Shown is the position of the die for solidification of the melt

Photo 2: The resulting casting of the pump body before being ejected from the die