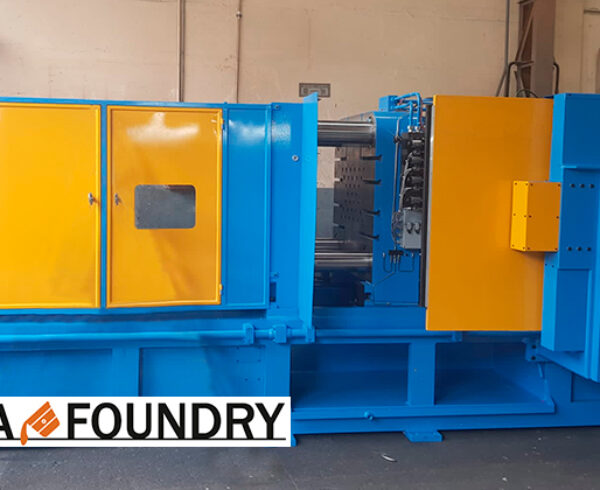

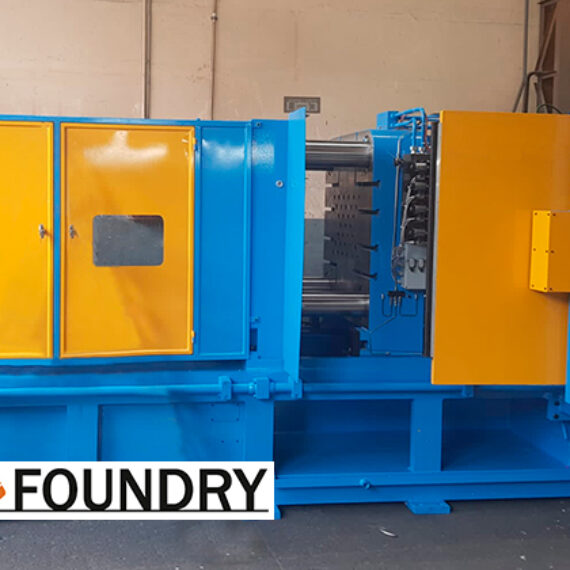

New design of a stationary gravity die casting machine for the production of large aluminum castings, which is distinguished by increased strength and reliability, as well as high forces of opening the die has been developed by SA – Foundry sp. z o.o. (Poland) at the request of customers.

Fig.1. The stationary gravity die casting machine ALG-S-1400×1400 from SA-Foundry sp. z o.o. (Poland)

The new gravity die casting machine is also equipped with a lower and upper ejection system and is adapted to apply additional pressure on the melt during crystallization (modern Squeeze Casting technology for obtaining high mechanical properties of the casting material).

The main parameters of the stationary gravity die casting machine ALG-S-1400×1400 from SA – Foundry sp. z o.o. presented below:

1. Main parameters

- Overall dimensions of plates: 1400 x 1400 mm

- Die dimensions: 1200 x 840 mm

- Columns diameter: 100 mm

- Plates thickness: 90 mm

- Lower plate height from floor level: 500 mm

- Machine working modes: automatic, manual

- Overall dimensions of the machine (without control cabinet): length – 2000 mm, width – 1854 mm, height – 3100 mm.

- Machine weight (without control cabinet): 6.500 kg

2. Hydraulic system parameters

- Diameter of working cylinders for die opening: 150 mm (four cylinders)

- Lower ejection cylinder diameter: 140 mm (one cylinder)

- Upper ejection cylinder diameter: 75 mm (four cylinders)

- Side cylinder diameter: 100 mm (one cylinder per side)

- Hydraulic system pressure: at least 140 bar

- Hydraulic consumption: at least 100 liters per minute

3. Control system

- The control cabinet is based on the Siemens S7 PLC controller (or similar PLC Omron, Mitsubishi) and the Siemens TP1200 (or similar Omron, Mitsubishi) process visualization system (touchscreen display).

- The control system provides a mode of automatic operation according to the parameters set by the technologist in advance and manual control of all hydraulic cylinders during start up of the new die.