Description

It is a powder flux used for removing nonmetallic

inclusions (oxide layers, carbides and others)

in pure lead and lead-based alloys, drossing off and

covering surface under melting. The dry and powdertype

dross with low metallic content was obtained after

cleaning operation by this flux. Improving the mechanical

properties of pure lead and lead-based alloys. Flux does

not react with crucible or furnace lining.

Applications

Cleaning, covering and drossing off

melt of pure lead and lead-based alloys under melting

procedure in lead scrap recycling. Cleaning pure lead and

lead-based alloys for wide range of casting techniques

and different types of furnaces.

Method of use

1. In case of lead scrap recycling covering-refining

flux introduces in melt stepwise with every part

of batch addition. The finish treatment is doing

before melt pouring. Intensive stirring of melt

promotes full reaction. After reaction the melt rest

time must be 10 minutes. The melt can be pouring

after skimming the dross.

2. In case of pure lead and lead-based alloys cleaning

for casting covering-refining flux introduces in

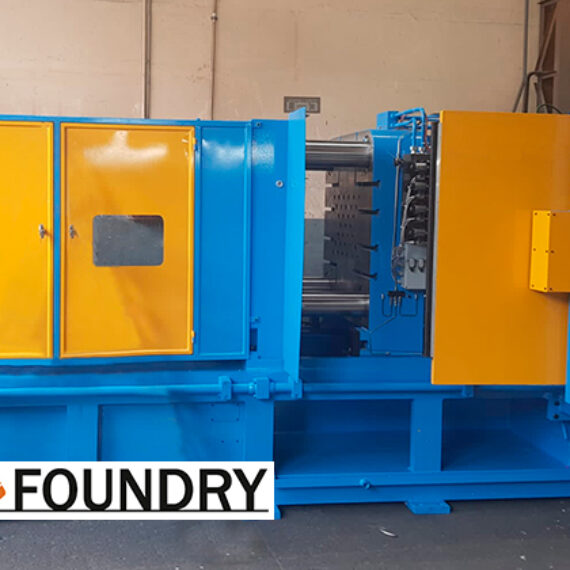

melt by hand foundry plunger under melt surface.

Intensive stirring of melt promotes full reaction.

After reaction the melt rest time must be 10 minutes.

The melt can be pouring after skimming the

dross.

For all applications the temperature of treatment must

be above 400°С.