Description

It is boron containing flux in form of tablets

used for oxygen and hydrogen removal from copperbased

alloys. The flux is suitable for pure copper and all

copper-based alloys (brass, bronze, others). The tablets

release a quantity (around 90% of tablet weight) of boron

in melt. Well known that boron is one of the most effective

deoxidizer for copper without harmful effect of reducing

the electrical conductivity. Also the addition of boron in

copper-based alloys is the grain refining effect. As result,

the boron containing flux improves the mechanical and

physical (first of all electrical conductivity) properties of

pure copper and copper-based alloys.

Applications

Oxygen and hydrogen removal operation

in pure copper and copper-based melt under melting /

holding procedure. Improving the mechanical properties

of pure copper and copper-based alloys for wide range of

casting techniques (continuous casting for electric wire

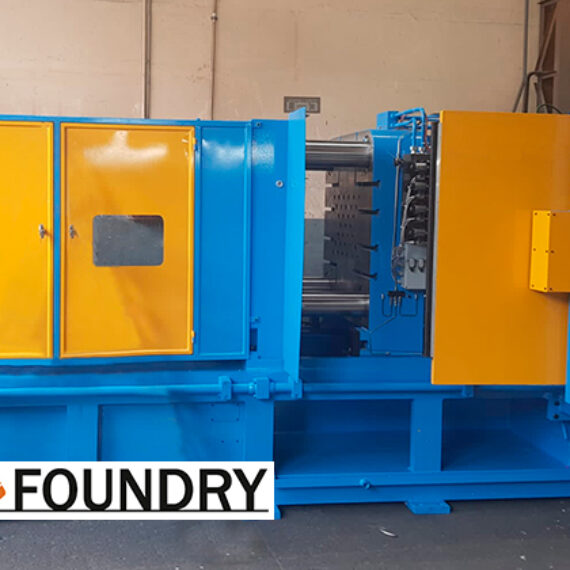

production, high pressure die casting, low pressure die

casting, gravity casting in permanent and sand molds,

others) and different furnace types.

Method of use

1. The boron containing tablets introduce in melt by

degassing plunger tool under melt surface to the bottom

of furnace crucible or furnace hearth.

2. The temperature of treatment must be above 900°С.

3. The degassing plunger must be in melt till ending of

reaction.

4. After reaction the melt rest time must be 1-3 minutes.

5. The melt can be pouring after skimming the dross.