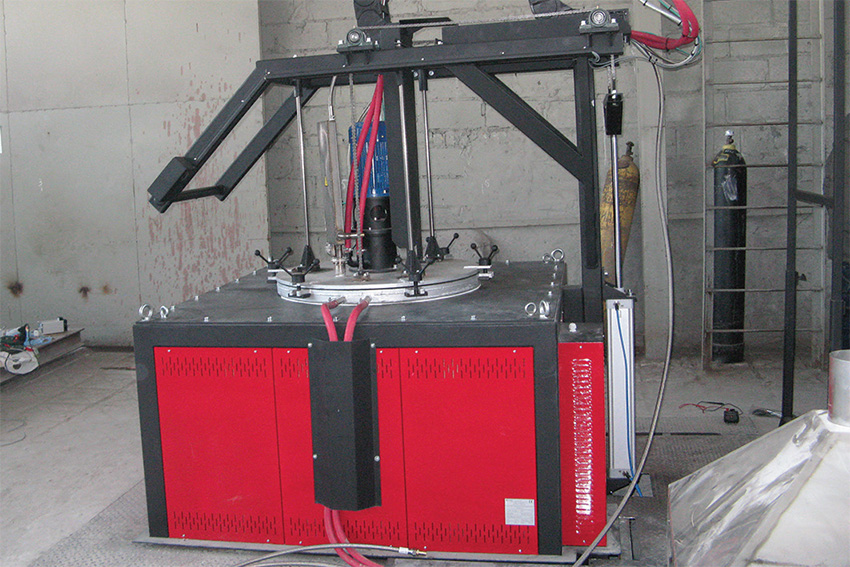

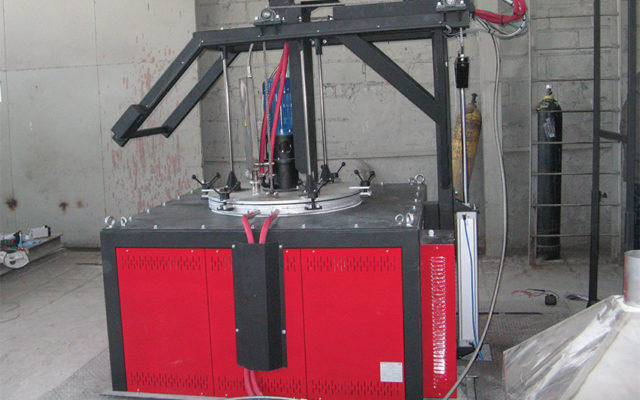

A modern thermal furnace (PG 700/650 A) is designed for thermal and thermochemical treatment of parts in a gas-tight retort with the forced atmosphere circulation.

A modern thermal furnace (PG 700/650 A) is designed for thermal and thermochemical treatment of parts in a gas-tight retort with the forced atmosphere circulation.

Made of modern high-quality lining materials: high-temperature-resistant concrete, lightweight brick and fibrous materials of SIBRAL (Germany) for minimal electricity consumption and high temperature uniformity in the furnace chamber.

Made of KANTHAL A1 (Sweden) resistance wire and placed on ceramic tubes for uniform heating of the furnace chamber.

The temperature and the process of thermochemical and thermal treatment are controlled by E5CС-HT programmable device from (“Omron”, Japan).

Heat-resistant steel of the grade 1.4845: EN 10095-1999. The retort has a hemispherical bottom.

– The electric motor power of the fan: 2 kW, 1,500 rpm.

– The diameter of the fan is 350 mm.

– Material of the fan and the lower plate: heat-resistant steel of the grade 1.4845: EN 10095-1999.

– Cooling of the seal of the fan shaft in the lid – with water.

thermal furnaces

thermal furnaces

SA-Foundry sp. z o.o. is a team of specialists who have many-year experience in the implementation of advanced process solutions for the production of castings and half-finished products from non-ferrous metals and alloys (aluminium, copper, zinc, lead) with improved cast properties.

SA-Foundry sp. z o.o. specialists continue scientific cooperation with a number of

In October 2023, SA-Foundry sp. z o.o. completed the development of a

At the end of September 2022 SA-Foundry sp. z o.o. supplied the

SA Foundry sp. z o.o. (Poland) – a trading partner of a

Address

street Lipowa 3D, 30-702 Krakow, POLAND

Numer KRS: 0000624462

REGON: 364765255, NIP: 6772404829

Phone

+48 511 480-980

E-Mail

foundrysa@gmail.com