SA Foundry sp. z o.o. (Poland) – a trading partner of a well-known Canadian manufacturer of melting furnaces for non-ferrous alloys, offers a new series of furnaces.

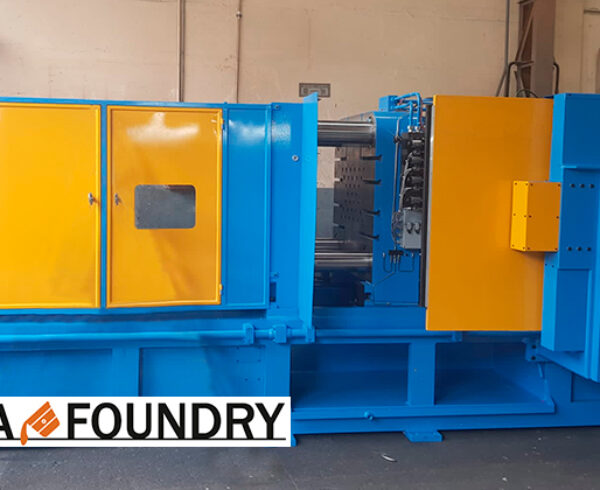

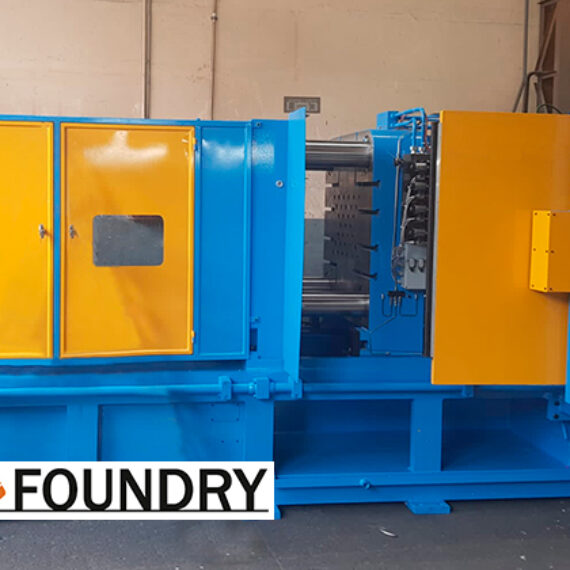

Gas furnaces of the GM-E series have a compact shaft design. These furnaces are designed to be placed near the High Pressure Die Casting machines or gravity casting machines. This series of furnaces is equipped with an automatic loading system to automate charge loading. Robust design and modern lining materials provide high performance furnaces and a long service life.

Furnaces are characterized by low metal loss and high quality of the resulting aluminum melt.

Photo. 1: Gas furnace mod. GM—E-3300

GM-E furnaces are controlled by modern PLC controllers with a visualization system.

SA-Foundry offers a wide range of GM-E series furnaces for foundries of various capacities.

Table 1: Model range of GM-E series gas furnaces for foundries of various capacities offered by SA-Foundry

Furnace model |

Furnace capacity, kg |

Melting rate, kg Al/hour |

GM-E-770 |

350 |

109 |

GM-E-1100 |

500 |

155 |

GM-E-1400 |

650 |

187 |

GM-E-1400 |

800 |

250 |

GM-E-2050 |

950 |

300 |

GM-E-2600 |

1200 |

365 |

GM-E-3300 |

1500 |

465 |

GM-E-4400 |

2000 |

750 |

The GM-E furnaces series has an optimal price/quality ratio.

Operation video of GM-E Series gas shaft furnace