SA-Foundry sp. z o.o. offers reliable modern equipment on the basis of roll presses for processing and preparing raw materials for various purposes.

SA-Foundry sp. z o.o. offers reliable modern equipment on the basis of roll presses for processing and preparing raw materials for various purposes.

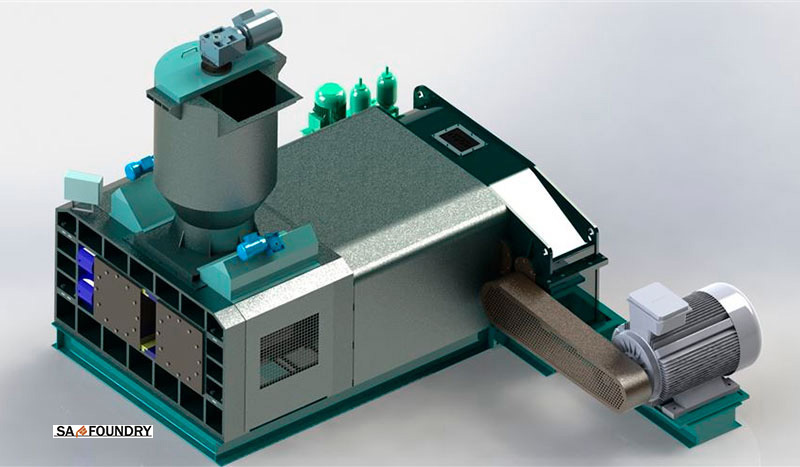

Photo 1: Roller briquetting press with a capacity of 1.000 kg per hour, model ARP-1

High pressure roller briquetting presses are designed to produce briquettes from various powder raw materials: coal fines and coal dust, lime powder, soda ash, various salts, sodium carbonate, fluorite powder, slag after smelting aluminum, iron powder, converter dust, ferrosilicon powder, chromium powder, magnesium powder, powder of refractory materials and other raw materials. Also, it is successfully used to obtain fuel briquettes from various organic raw materials including charcoal.

The resulting briquettes are highly durable, convenient for transportation, provide efficient processing and using of raw materials. Briquettes obtained using dry briquetting under high pressure can have various shapes: oval, egg shape, pillow shape, cube shape, etc., in accordance with customer requirements. The performance of briquetting presses can also vary in the range from 1 to 20 tons per hour.

The main technical parameters of the roll briquette press are presented in table. 1 using the ARP-1 model as an example.

Table 1: Main technical parameters of the roll briquette press ARP-1, with a productivity of 1.000 kg per hour

| Parameters | Parameter value |

| Productivity, kg/h | 1000 |

| The minimum density of the finished briquette, g/cm3 | 0,8 |

| The size of the powder raw material (fraction), mm | 0 – 3 |

| Powder raw material feed | vertical using screw loader |

| Feed drive | electric motor with gear |

| Drive of powder raw material feed shatter | two servomotors |

| Power of the roll drive electric motor, kW | 18,5 |

| Total input power, kW | 23,4 |

| Number of hydraulic cylinders | 4 |

| Maximum pressure in a hydraulic system, bar | 150 |

| Mode of operation | manual, semiautomatic |

| Diameter of work rolls, mm | 300 |

| Hardness of steel work rolls, HV (Vickers) | 650 |

| Roll speed | adjustable |

| Number of gear stages | 4 |

| Maximum gear torque, Nm | 3500 |

Photo 2: Examples of briquettes from various powder raw materials: coal dust, salt, aluminum slag, electric arc furnace dust

Photo 3: Roll press for dry granulation

Dry granulation equipment allows to compact powder particles of various raw materials into granules of a certain size. In dry granulation, the powder mixture without the addition of liquid is compacted by applying considerable force to the powder.

Today, granulation is used very widely in various industries: in the chemical, petrochemical, pharmaceutical and metallurgical industries. Also in agriculture, one of the most popular applications for granulating raw materials is the production of granular fertilizers and feed. To date, the production of fuel pellets from waste wood and the agricultural sector (husk, straw, etc.) is very common.

equipment for briquetting and granulation

SA-Foundry sp. z o.o. is a team of specialists who have many-year experience in the implementation of advanced process solutions for the production of castings and half-finished products from non-ferrous metals and alloys (aluminium, copper, zinc, lead) with improved cast properties.

SA-Foundry sp. z o.o. specialists continue scientific cooperation with a number of

In October 2023, SA-Foundry sp. z o.o. completed the development of a

At the end of September 2022 SA-Foundry sp. z o.o. supplied the

SA Foundry sp. z o.o. (Poland) – a trading partner of a

Address

street Lipowa 3D, 30-702 Krakow, POLAND

Numer KRS: 0000624462

REGON: 364765255, NIP: 6772404829

Phone

+48 511 480-980

E-Mail

foundrysa@gmail.com